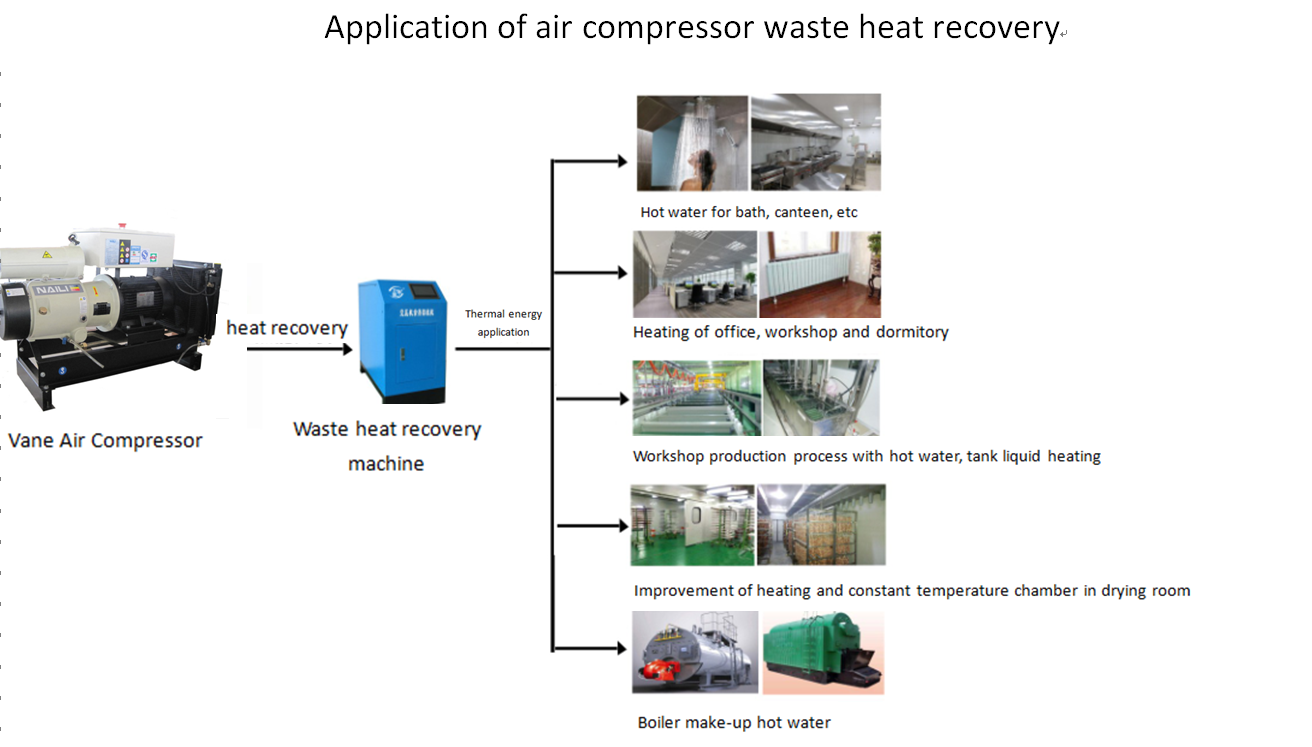

Technical parameters of air compressor waste heat recovery machine

Advantages of air compressor waste heat recovery machine:

1. Zero operating cost

No gasoline, no coal, no electricity consumption. The waste heat of the air compressor is fully utilized. As long as the air compressor is running, no additional energy consumption is required, hot water can be produced.

2. Safe and reliable

Specially designed low resistance heat exchanger is adopted, The resistance of the system to the oil circuit has hardly increased, After installing the waste heat recovery machine, the air compressor control system remains unchanged, Start and stop of waste heat recovery machine, It has no effect on the original air compressor system, The original air compressor system can operate as usual.

3. Improve the air compressor operation condition

The operation temperature of air compressor is reduced, which can solve the problem of high temperature shutdown of air compressor in summer, prolong the service life of the machine and reduce the maintenance cost, The replacement time limit of oil, oil grid and oil-gas separator separator separator is increased, and the replacement period of equipment is correspondingly extended。

4. Intelligent design

Full automatic operation, water temperature and level intelligent control, no need for special management.

5. Safety and environmental protection

The hot water temperature of waste heat recovery machine is between 50-80 degrees, which can be set automatically.

(Conventional circulation type)

Model | Suitable for Compressor (KW/HP) | Waste heat recovery (KW) | Outlet water temperature | Water yield (Temp rise 40℃) | Pipe Diameter (Oil / water pipeline) | Dimensions (mm) (LxWxH) |

NL-20A/DY | 15KW/20HP | 12 | 55℃-80℃ | 0.26 m3/h (40℃) | DN25/DN32 | 700x400x800 |

NL-30A/DY | 22KW/30HP | 17.6 | 55℃-80℃ | 2.38 m3/h (40℃) | DN25/DN32 | 700x400x800 |

NL-40A/DY | 30KW/40HP | 24 | 55℃-80℃ | 0.52 m3/h (40℃) | DN25/DN32 | 700x400x800 |

NL-50A/DY | 37KW/50HP | 29.6 | 55℃-80℃ | 0.64 m3/h (40℃) | DN25/DN32 | 700x400x800 |

NL-60A/DY | 45KW/60HP | 36 | 55℃-80℃ | 0.78 m3/h (40℃) | DN25/DN32 | 750x400x870 |

NL-75A/DY | 55KW/75HP | 44 | 55℃-80℃ | 0.95 m3/h (40℃) | DN25/DN32 | 750x400x870 |

NL-100A/DY | 75KW/100HP | 60 | 55℃-80℃ | 1.3 m3/h (40℃) | DN50/DN50 | 750x400x870 |

NL-125A/DY | 90KW/125HP | 72 | 55℃-80℃ | 1.6 m3/h (40℃) | DN50/DN50 | 850x460x905 |

NL-150A/DY | 110KW/150HP | 88 | 55℃-80℃ | 1.9 m3/h (40℃) | DN50/DN50 | 850x460x905 |

(Direct heating type)

Model | Suitable for Compressor (KW/HP) | Waste heat recovery (KW) | Outlet water temperature | Water yield (Temp rise 40℃) | Pipe Diameter (Oil / water pipeline) | Dimensions (mm) (LxWxH) |

NL-20A/Z | 15KW/20HP | 12 | 55℃-80℃ | 0.26 m3/h (40℃) | DN20/DN20 | 700x400x800 |

NL-30A/Z | 22KW/30HP | 17.6 | 55℃-80℃ | 2.38 m3/h (40℃) | DN20/DN20 | 700x400x800 |

NL-40A/Z | 30KW/40HP | 24 | 55℃-80℃ | 0.52 m3/h (40℃) | DN20/DN20 | 700x400x800 |

NL-50A/Z | 37KW/50HP | 29.6 | 55℃-80℃ | 0.64 m3/h (40℃) | DN25/DN20 | 700x400x800 |

NL-60A/Z | 45KW/60HP | 36 | 55℃-80℃ | 0.78 m3/h (40℃) | DN25/DN20 | 750x400x870 |

NL-75A/Z | 55KW/75HP | 44 | 55℃-80℃ | 0.95 m3/h (40℃) | DN25/DN20 | 750x400x870 |

NL-100A/Z | 75KW/100HP | 60 | 55℃-80℃ | 1.3 m3/h (40℃) | DN32/DN25 | 750x400x870 |

NL-125A/Z | 90KW/125HP | 72 | 55℃-80℃ | 1.6 m3/h (40℃) | DN32/DN25 | 850x460x905 |

NL-150A/Z | 110KW/150HP | 88 | 55℃-80℃ | 1.9 m3/h (40℃) | DN32/DN25 | 850x460x905 |

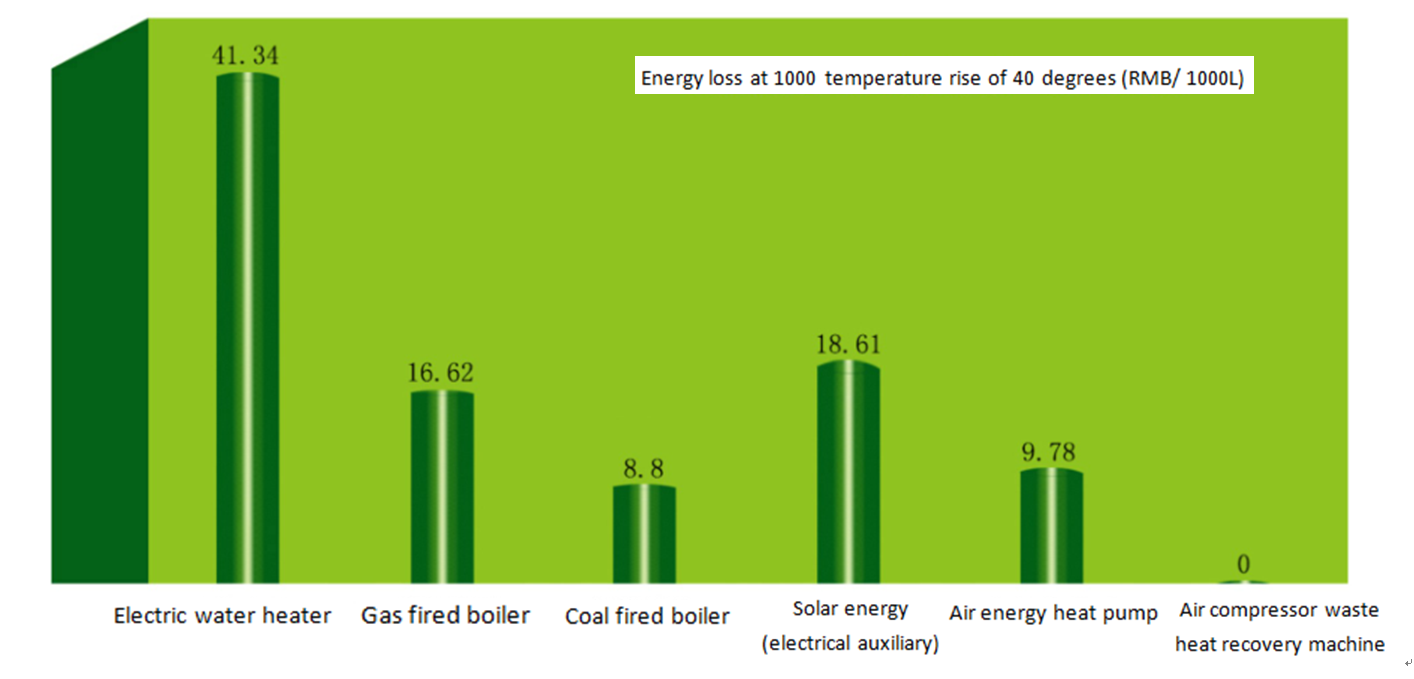

How much energy is needed to heat a ton of water from 15 ℃ to 55 ℃