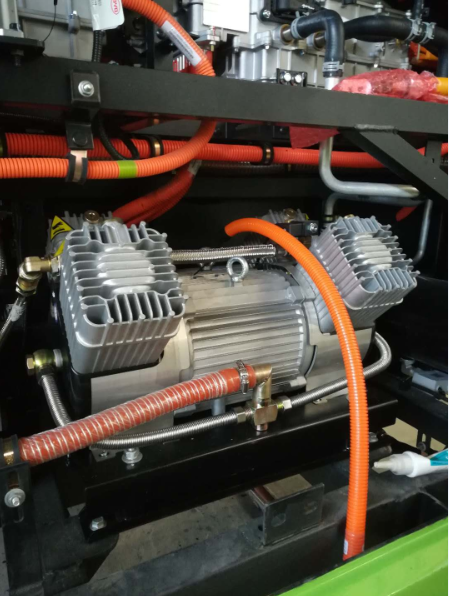

Which is classic series of compressor of NAILI Manufacturing since 2017 and the purpose for the easier maintenace, Environment; >HV series have two stable 24VDC fans with high speed to release the heat from of Oilfree Piston compressor -

now they are widely used in Electrical bus, Electric trucks, Mini van, Dental care and Construction machinery and so on;

The cutting edges of Oilfree piston NAILI has more Long lasting working life than other similar compressor in the market;

Constantly working more than 18,000H;

100% Imported from Germany for Piston Head and O-ring seal, And even bearings;

IP67 protection level can make it working under the water;

Lower Maintenance needs,8000H SERIVCE FREE

Clean and Contaminant-Free Air: Oil-free compressors do not require lubricating oil in the compression chamber, ensuring that the compressed air is free from oil contaminants. This makes them ideal for applications where clean and pure air is crucial, such as in food processing, pharmaceuticals, electronics, and medical devices.

Reduced Maintenance: Oil-free compressors have fewer components, reducing the need for regular maintenance and minimizing the risk of oil-related issues like oil leaks or oil changes. This leads to lower maintenance costs and increased uptime.

Environmental Friendliness: Since oil-free compressors don't use lubricating oil, there is no risk of oil spills or environmental contamination. They are more environmentally friendly and compliant with strict regulations, making them a sustainable choice.

Energy Efficiency: Oil-free compressors are often designed for improved energy efficiency. They can operate at varying speeds or have better control mechanisms to match air supply with demand, reducing energy consumption and operating costs.

Lower Operating Temperatures: Oil-free compressors generate less heat during operation because there is no friction between the pistons and oil. This can help extend the lifespan of components and reduce the risk of overheating.

Quiet Operation: Oil-free compressors tend to produce less noise compared to oil-lubricated counterparts. This can be especially important in applications where noise levels need to be minimized, such as in laboratories or residential areas.

High Purity Air: In industries where air quality is critical, such as in the production of semiconductors or pharmaceuticals, oil-free compressors are essential to ensure the highest level of air purity.

Versatility: Oil-free piston compressors are versatile and can be used in various applications, including dental offices, laboratories, painting, and woodworking, where oil contamination would be detrimental.

Ease of Installation: Oil-free compressors are often easier to install because they don't require additional equipment like oil separators or condensate management systems.

Medical: Oil-free compressors are used in medical facilities to supply clean, dry compressed air for various applications, including ventilators, anesthesia machines, and dental equipment, where air purity is critical to patient health.

Pharmaceuticals: Pharmaceuticals manufacturing relies on oil-free air compressors to ensure product purity and prevent contamination in processes such as tablet coating, packaging, and air agitation of liquids.

Food and Beverage: Oil-free compressors are essential for the food and beverage industry to maintain product quality and safety. They are used for tasks like bottling, canning, and pneumatic conveying of food products.

Electronics: The electronics industry utilizes oil-free compressed air in cleanroom environments for semiconductor manufacturing, circuit board assembly, and sensitive instrument calibration.

Laboratories: Oil-free compressors are employed in research laboratories for various applications, such as chromatography, gas chromatograph-mass spectrometry (GC-MS), and general laboratory air supply.

Painting and Coating: In automotive, aerospace, and industrial painting applications, oil-free compressors are used to provide clean, dry air for spray guns and pneumatic paint systems to achieve a high-quality finish.

Environmental Testing: Environmental testing labs use oil-free compressors to provide precise and contamination-free air for environmental chambers, air sampling equipment, and pollution monitoring instruments.

Chemical Industry: In chemical processing and laboratories, oil-free compressors are used for air-driven chemical reactions, gas sample analysis, and chemical testing.

Automotive: Automotive manufacturing relies on oil-free compressors for applications like pneumatic tool operation, tire inflation, and paint shop processes, where oil contamination could affect product quality.

Printing: The printing industry uses oil-free compressed air for tasks like operating printing presses and maintaining consistent ink viscosity to ensure print quality.

Beverage Dispensing: Oil-free compressors are used in beverage dispensing systems, such as soda fountains and beer taps, to provide clean and odor-free air for carbonation and dispensing.

Wastewater Treatment: In wastewater treatment plants, oil-free compressors are used for aeration processes, ensuring that the air introduced into the water remains free of oil contaminants.

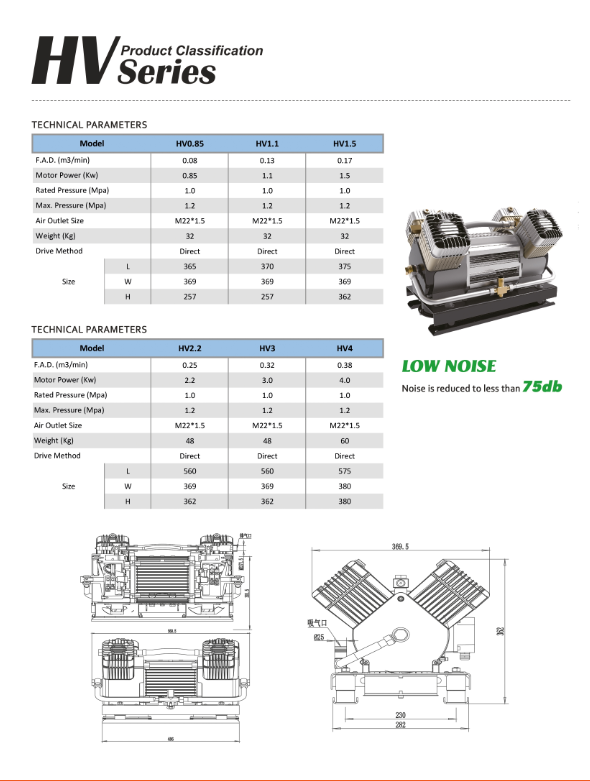

| Model | Air delivery | Pressure | Power kw | Outlet size | Weight |

HV1.5 | 0.17 | 10bar | 1.5 | M22×1.5 | 32 |

HV2.2 | 0.22 | 10bar | 2.2 | M22×1.5 | 48 |

HV3.0 | 0.32 | 10bar | 3.0 | M22×1.5 | 48 |

HV4.0 | 0.38 | 10bar | 4.0 | M22×1.5 | 60 |