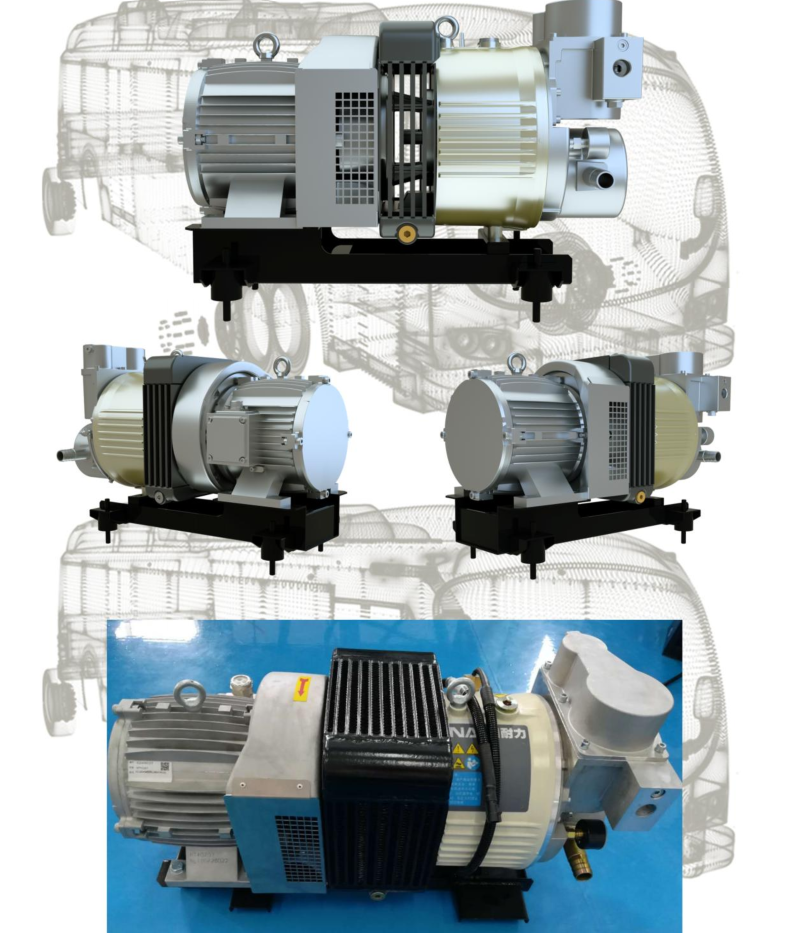

AZF series Electrical Bus Air Compressor is the latest designs for E-bus and other E-vehicles (Automotives) made by NAILI;

Our electric vehicle compressor series has been engineered to deliver reliable and efficient performance while meeting the demanding requirements of modern electric mobility systems. Built with precision, each model—from the AZF2.2 H and AZF3.0 H to the AZF4.0 H, and their high-pressure counterparts, AZF2.2 HH, AZF3.0 HH, and AZF4.0 HH—offers consistent air displacement and exhaust pressure for optimal performance. Operating at a stable temperature of 110°C, these compressors incorporate a standardized M22 x 1.5 vent design and lightweight construction (ranging from 42 to 50 kg), making them ideal for compact spaces while maintaining exceptional power output measured in kW.

Separation vertical installed;

The oil carry-over is decreased to 1,5 PPM to eliminate downstream oil problems

Oil indicator fixed one two sides;

Improved accessibility for easy, quick and safe oil replacement with PTFE drain tubes.

Easier replacement of all consumable parts on the compressor

Save maintenance time, requiring less maintenance skills with the easy replaceable filters and valves.

Precision Performance:

Each unit is designed to deliver exactly the right air displacement—ranging from 0.21 to 0.38 m³/min—and maintain stable exhaust pressures, either at 10 Bar (H models) or 12 Bar (HH models). This precision ensures that the compressors efficiently meet the specific pressure needs of modern electric vehicles.

Optimal Energy Efficiency:

Available in motor powers from 2.2 kW to 4.0 kW, the compressors are engineered for energy efficiency without compromising performance. This results in reduced energy consumption, making them a smart choice for sustainable mobility.

Superior Air Quality:

With an oil content of 3.0 PPM or less (and even 50 PPM in some models), the design ensures minimal contamination in the compressed air. This is especially important in electric vehicle applications, where air purity plays a crucial role in overall system reliability.

Compact and Lightweight Construction:

The units are designed to be lightweight (42 – 50 kg) and compact, which eases installation in limited spaces such as within vehicle architectures or dedicated EV charging stations.

Durability and Temperature Stability:

Operating at a stable temperature of 110°C, our compressors are built to handle continuous use while delivering long-term durability—an essential factor for the rigorous demands of electric vehicle systems.

Name

Model | Air displacement (m3/ min) | Exhaust pressure (Bar) | Motor Power (kW) | Oil Content (PPM) | Temperature | Vent size | Weight (kg) |

AZF2.2 H | 0.24 | 10 | 2.2 | 3.0 or less | 110 | M22 x 1.5 (inside) | 42 |

AZF3.0 H | 0.30 | 10 | 3.0 | 3.0 or less | 110 | M22 x 1.5 (inside) | 42 |

AZF4.0 H | 0.38 | 10 | 4.0 | 50 or less | 110 | M22 x 1.5 (inside) | 50 |

AZF2.2 HH | 0.21 | 12 | 2.2 | 3.0 or less | 110 | M22 x 1.5 (inside) | 42 |

AZF3.0 HH | 0.25 | 12 | 3.0 | 3.0 or less | 110 | M22 x 1.5 (inside) | 42 |

AZF4.0 HH | 0.32 | 12 | 4.0 | 50 or less | 110 | M22 x 1.5 (inside) | 50 |

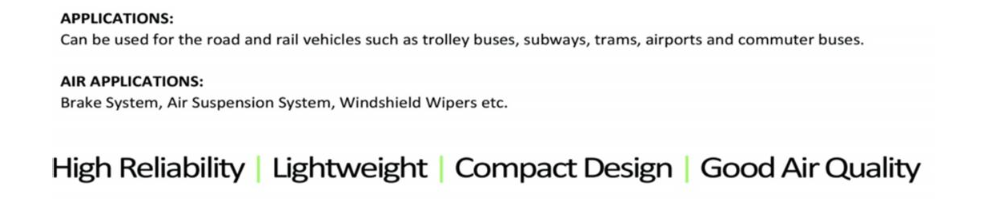

NAILI Rotary vane compressor types for All major bus builders like Yutong, BYD, Golden Dragon and other have chosen Naili compressors as their standard allowing Naili a 85% market share.

Naili can produce 80.000 units per year and welcomes new customer for standard compressors or specific development. IATF certified, R&D centre with all possible test equipment on site.